Portfolio

Every build is designed with reliability, efficiency, and real-world use in mind. Here are a few examples of how TRS Engineering delivers practical solutions for aerospace, instrumentation, and lab environments.

custom test systems

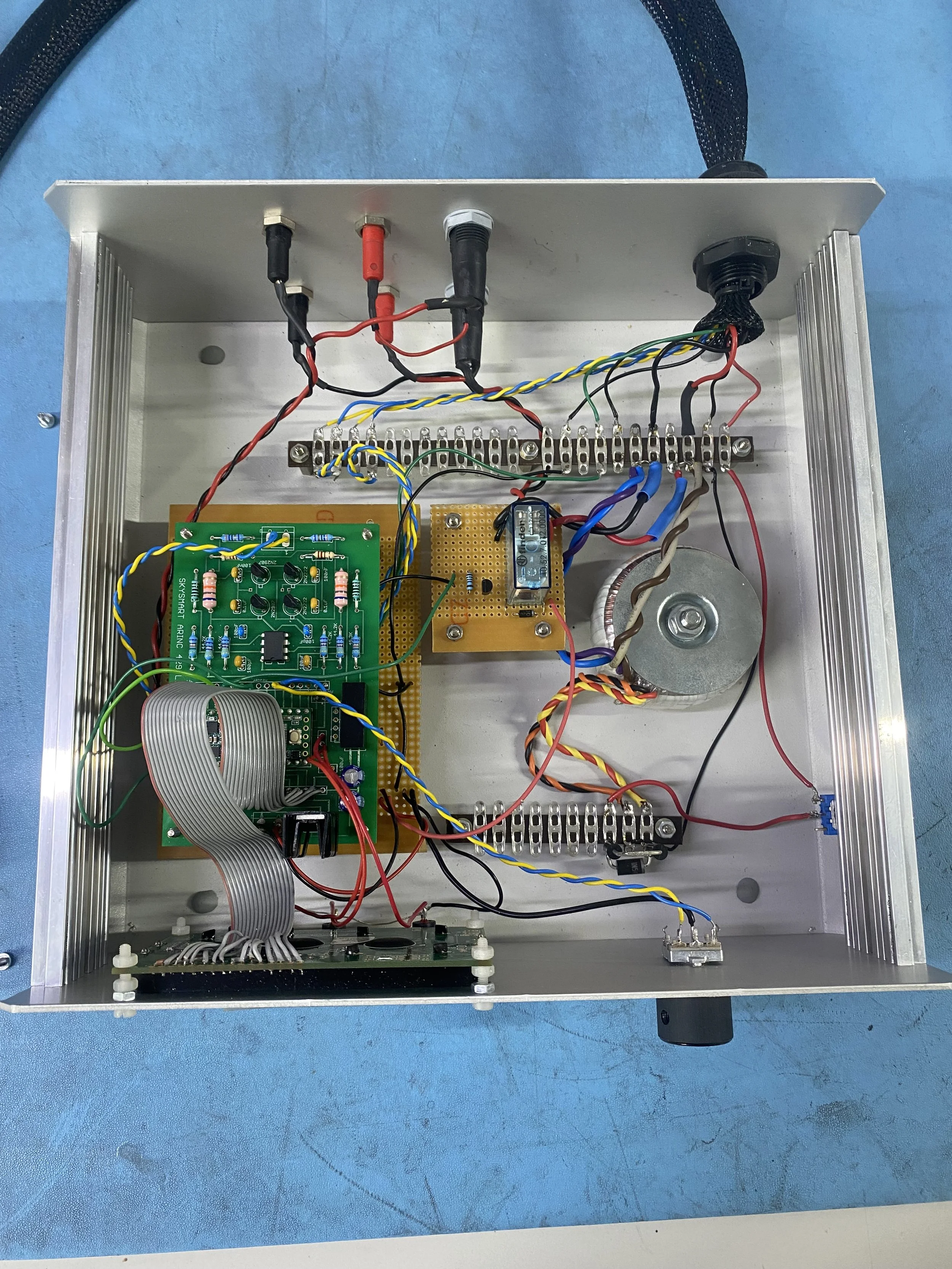

Vertical Speed Indicator Test Box

To reduce reliance on large, expensive, analogue test rigs, I designed and built a dedicated vertical speed indicator test box using microcontroller logic and ARINC 429 communication. This solution provided a faster and more efficient way to verify cockpit instruments, while ensuring accurate, repeatable results.

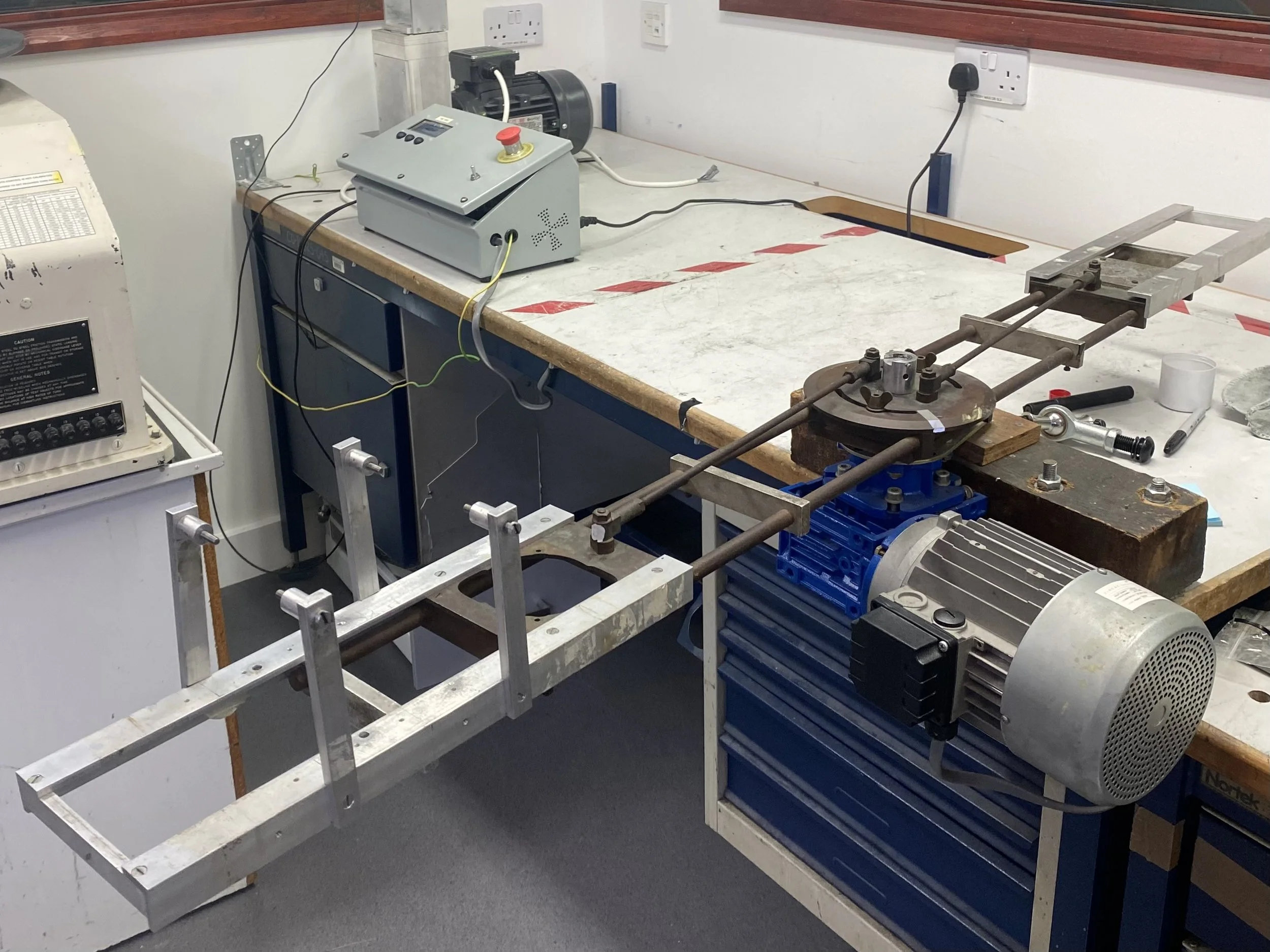

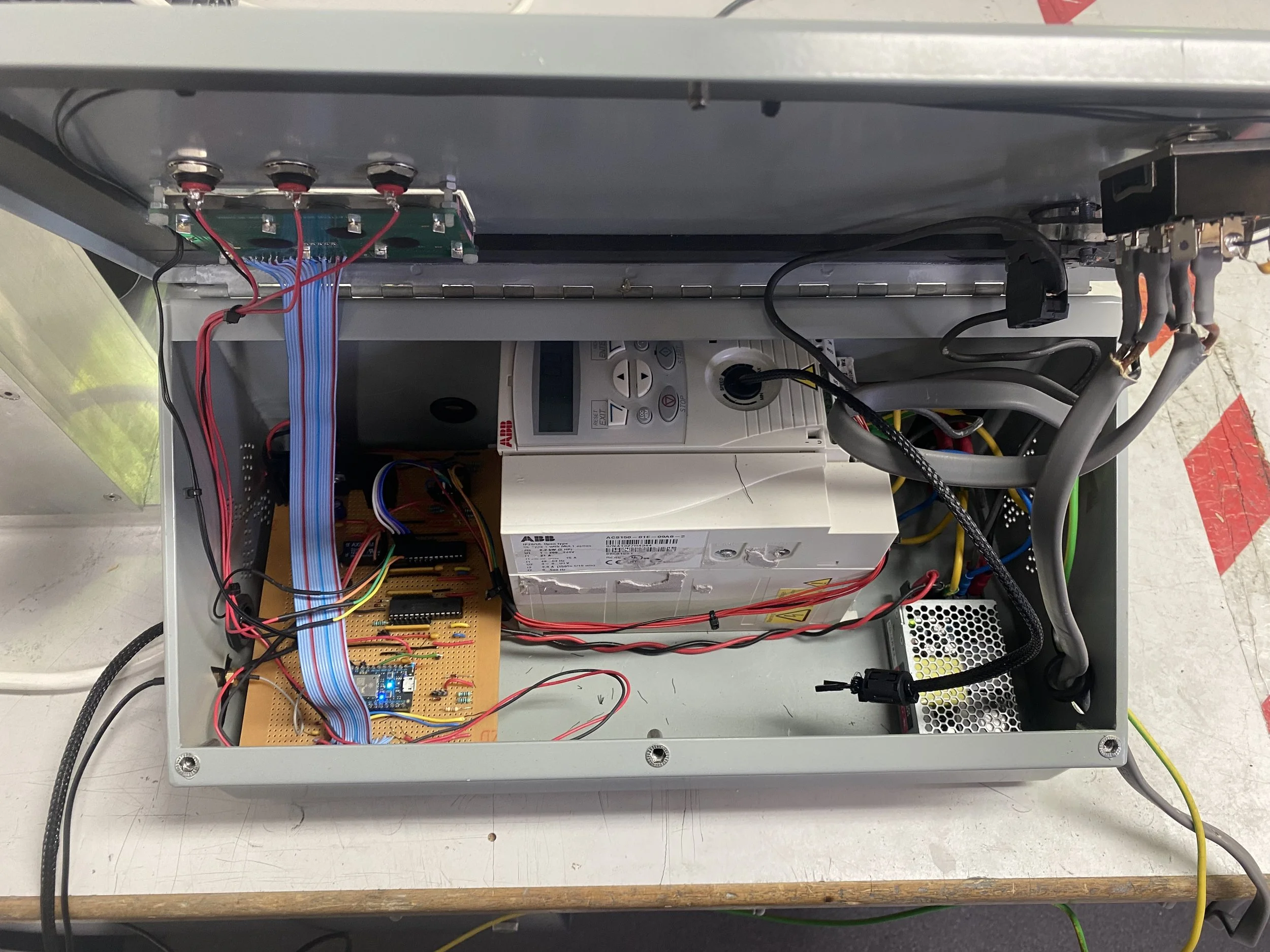

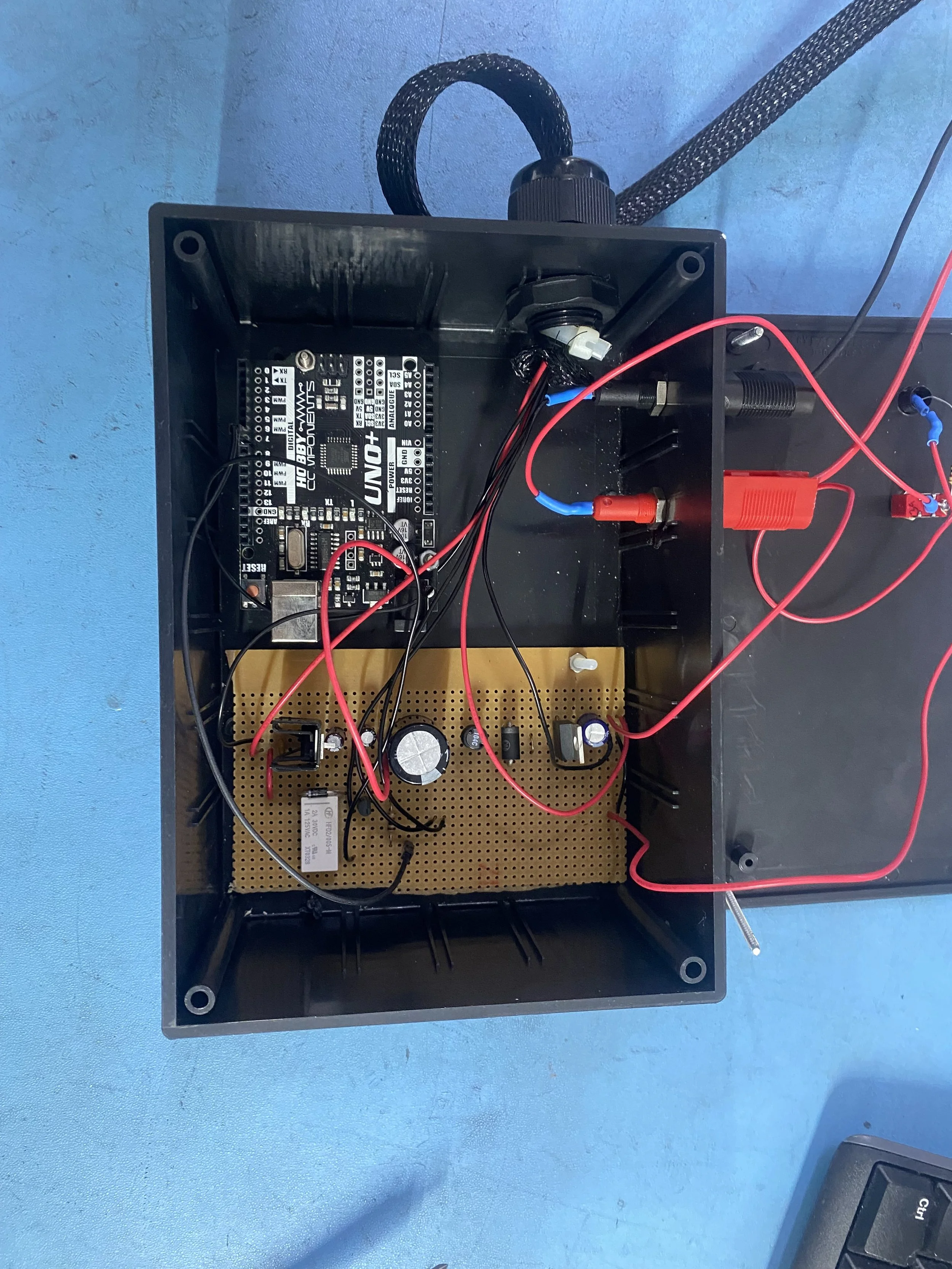

3-Phase Motor G-Meter Test Rig

Manual testing of vintage aircraft G-meters was slow and inconsistent, so I developed an automated rig powered by a WIFI enabled microcontroller. Connected to a custom web interface and database, it delivered real-time data capture and traceability. The system improved repeatability, cut operator workload, and streamlined the entire testing process.

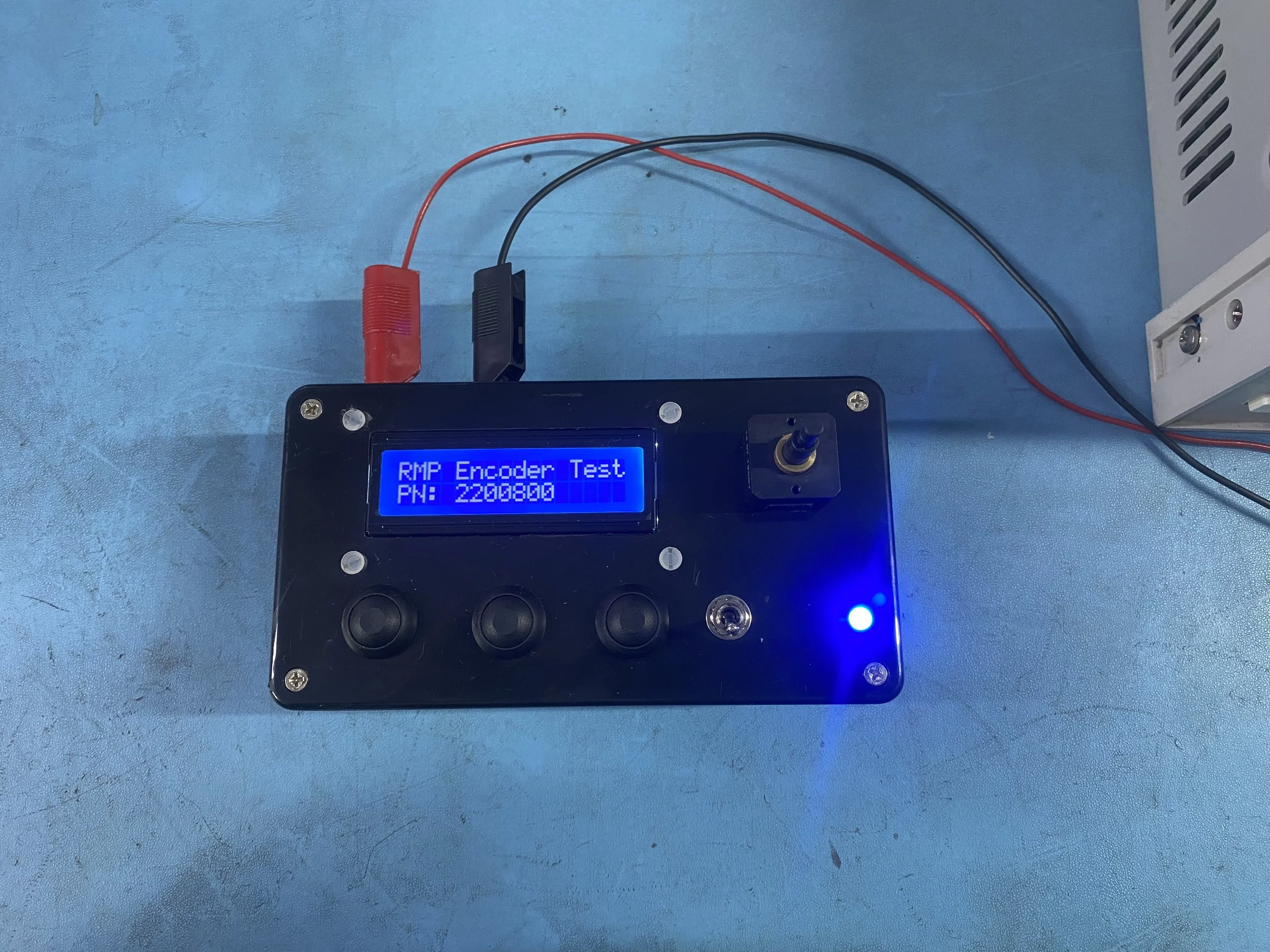

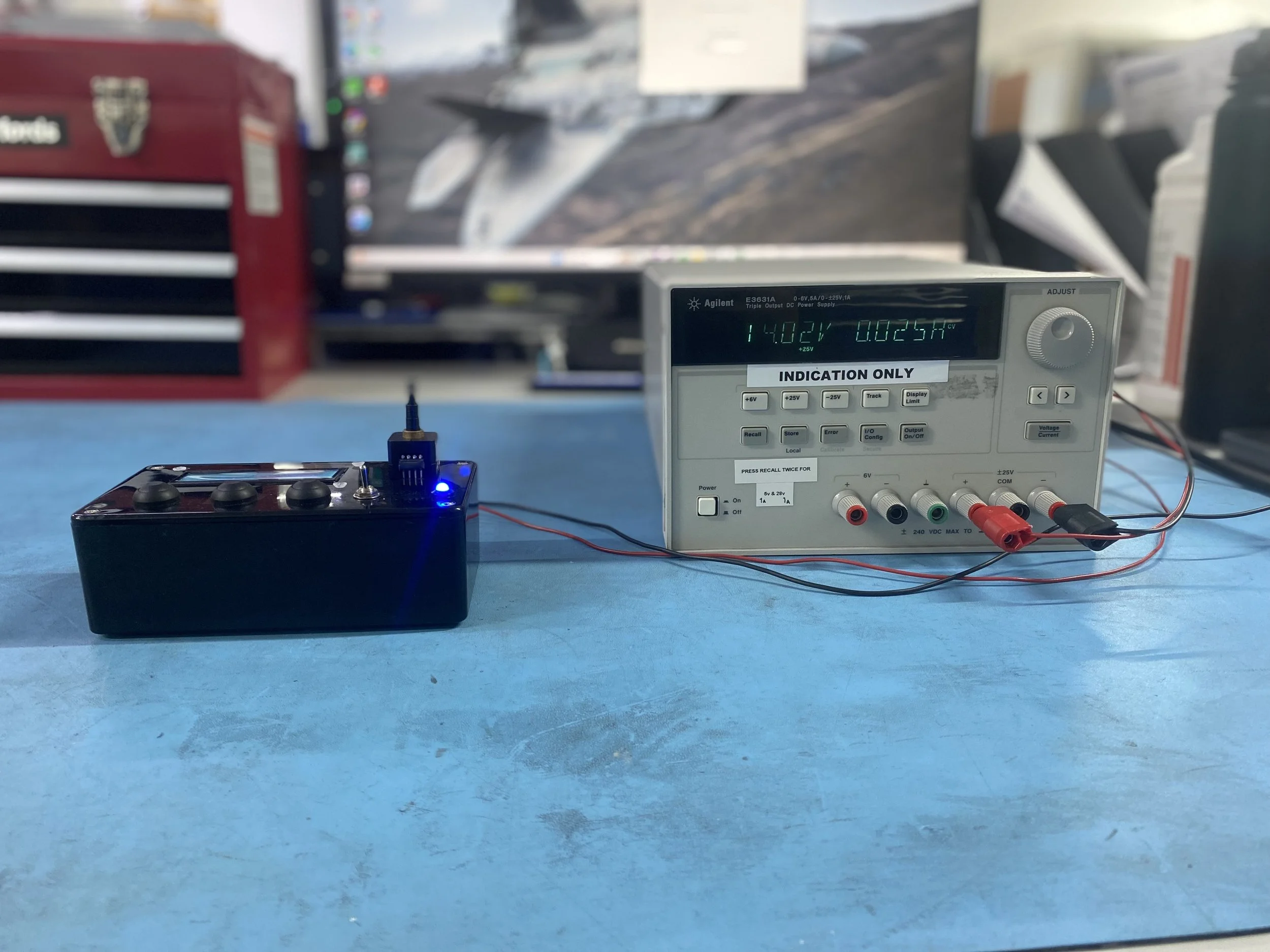

RMp encoder test box

Testing RMP encoders previously required a servicebale unit asseembly, creating bottlenecks and test rig downtime. I solved this by building a compact, purpose-built test box to validate encoders individually. This approach freed up valuable test rigs, accelerated fault isolation, and enabled faster turnaround on component-level issues.

Software tools

Fault Code Database & Failure Analysis Program

Troubleshooting avionics faults was often inconsistent and time-intensive. To address this, I created a Python-based analysis program that aggregates failure data from automated rigs, aligns it with quoted components, and calculates probability-based fault fixes. The result was a smarter, data-driven repair process that reduced turnaround times and improved accuracy.

Electronics Design

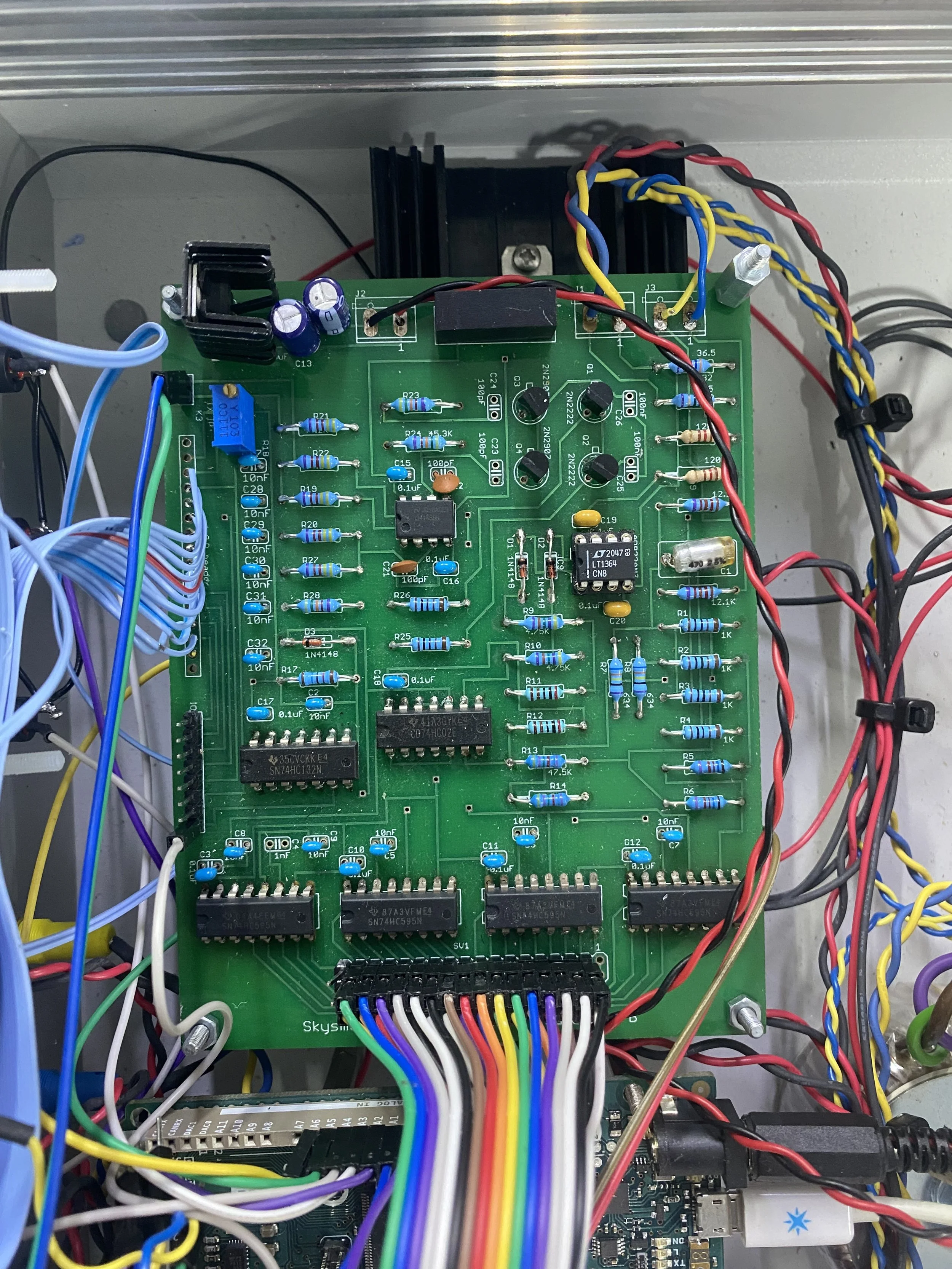

Custom ARINC 429 TX/RX PCB

Traditional ARINC 429 analysers are handheld devices that cannot easily interface with other software, forcing operators to check each label individually. This process is slow, manual, and prone to inconsistency. To overcome this, I designed a custom ARINC 429 transmit and receive PCB that connects directly to a microcontroller. The data can then be displayed in a clean, structured format on a test box, making it far easier to interpret. This approach not only speeds up testing but also ensures results are consistent, reliable, and directly integrated into wider automated systems.

RMp DISplay test box

RMP display testing previously required running full functional tests, with any adjustments forcing repeated restarts and heavy use of automated test rigs. To solve this, I built a dedicated RMP Display Test Box that placed the unit directly into display test mode. This allowed adjustments to be made immediately, freeing up rig capacity and significantly speeding up the testing process.